The Amazon: known as the 'lungs of the earth', but in reality all trees, plants and grasses, including bamboo, are a source of oxygen. Through photosynthesis, under the influence of sunlight, they convert water and carbon dioxide (CO2) into glucose (building block for biomass), water and oxygen:

6 CO2 + 12 H2O + photons ➔ C6H12O6 + 6 O2 + 6 H2O

(carbon dioxide + water + light energy ➔ glucose + oxygen + water)

The CO2 is then stored in the material, in the biomass as biogenic carbon, and in bamboo’s case in the stem. If the bamboo stem continues to grow and eventually dies, the CO2 is released back into the atmosphere. If the bamboo stem is harvested after the growth period, after 4 to 5 years, and processed into a sustainable and durable product, the carbon is locked in the material. Thus, in MOSO® bamboo products carbon is stored as long as the product is in use, and even longer if the material is reused or recycled e.g. to particle boards. When eventually burnt for energy, this may replace the use of fossil fuels, providing another carbon benefit.

Bio-based materials act as carbon locks

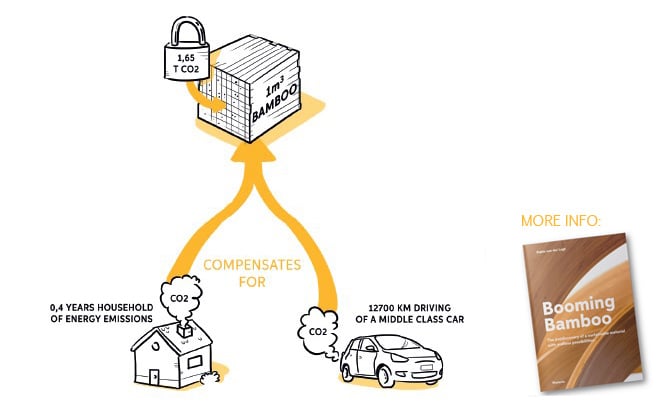

The amount of Construction Stored Carbon (CSC) can be as much as 1.662 ton CO2 per m³ of bamboo, looking at the heaviest materials such as Bamboo X-treme®. A positive side-effect of harvesting the bamboo stem is that the mother plant starts to produce new stems, and at the same time captures more CO2 in the forest, thus annually providing a surplus of new building material. In fact, because of the fast growth, the carbon stored in the durable products pool is higher for bamboo than for other bio-based materials, including most wood species, see this report.

How much carbon is locked in bamboo?

Calculating the CO2 captured in bio-based materials, including bamboo, can be done by looking at the carbon content following the European norms EN 16785-2 (for establishing bio-based content) and EN 16449 (originally designed for wood, may also be used for bio-based materials with similar biogenic carbon content). Around half of the mass of oven-dry bio-based material (wood / bamboo) consists of carbon. The ratio of the molecular weight of CO2 (44g/mol) to C (12g/mol) is 3.67. The CO2 captured by the durable products can be calculated rather simply based on the density of the bamboo species, taking into account the moisture and glue content. The greater the weight per m³, the more carbon is locked. For example, Bamboo X-treme®, with a density of 1150 kg/m³, consists of 90% bamboo (1010 kg/m³) with a moisture content of 12%, which is 902 kg / m³ dry biomass at 0% moisture content. Half of this mass, 453 kg/m³, is biogenic carbon content. Multiplied by the ratio of molecular weight of CO2 to C (3.67) results in 1662 kg CO2 /m³. This is higher than most wood species (e.g. pine at 450 kg/m³ locks around 737 kg CO2, bangkirai at 930 kg/m³ locks 1475 kg CO2) For custom-made calculations there are several easy-to-use carbon calculators available online, based on timber use, but these may also be used for other bio-based materials, such as bamboo. See, for example, the Centrum Hout CO2 calculator (Dutch Wood Center)

Avoiding CO2 emissions when bamboo substitutes CO2 intensive building materials

In cases where engineered bamboo material substitutes high CO2 intensive building materials, such as PVC and aluminium (e.g. for window frames, decking or cladding), CO2 emissions are avoided, known as the substitution effect. However, this added CO2 benefit is only applicable in cases where the bamboo material directly substitutes an abiotic material (thus does not apply when substituting another bio-based material). The substitution effect of the use of bio-based material in the building industry is around 1.5 tons CO2 per ton of bio-based material used instead of an abiotic material alternative. [1] This is a conservative number compared to other published substitution factors. For example, a commonly referenced meta-analysis applied a factor of 3.9 tons CO2 avoided per ton of bio-based material used instead of non-renewable materials. [2]

Do you want to know more about bamboo and carbon storage? Read "Booming Bamboo: The (re)discovery of a Sustainable Material with Endless Possibilities"

Sources